Dyna Metal is committed to advancing sustainable business growth in alignment with the Sustainable Development Goals (SDGs).

Click here to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Dyna Metal upholds a unified global code of ethics in alignment with the Daido Metal Group, ensuring integrity and accountability in every aspect of our operations.

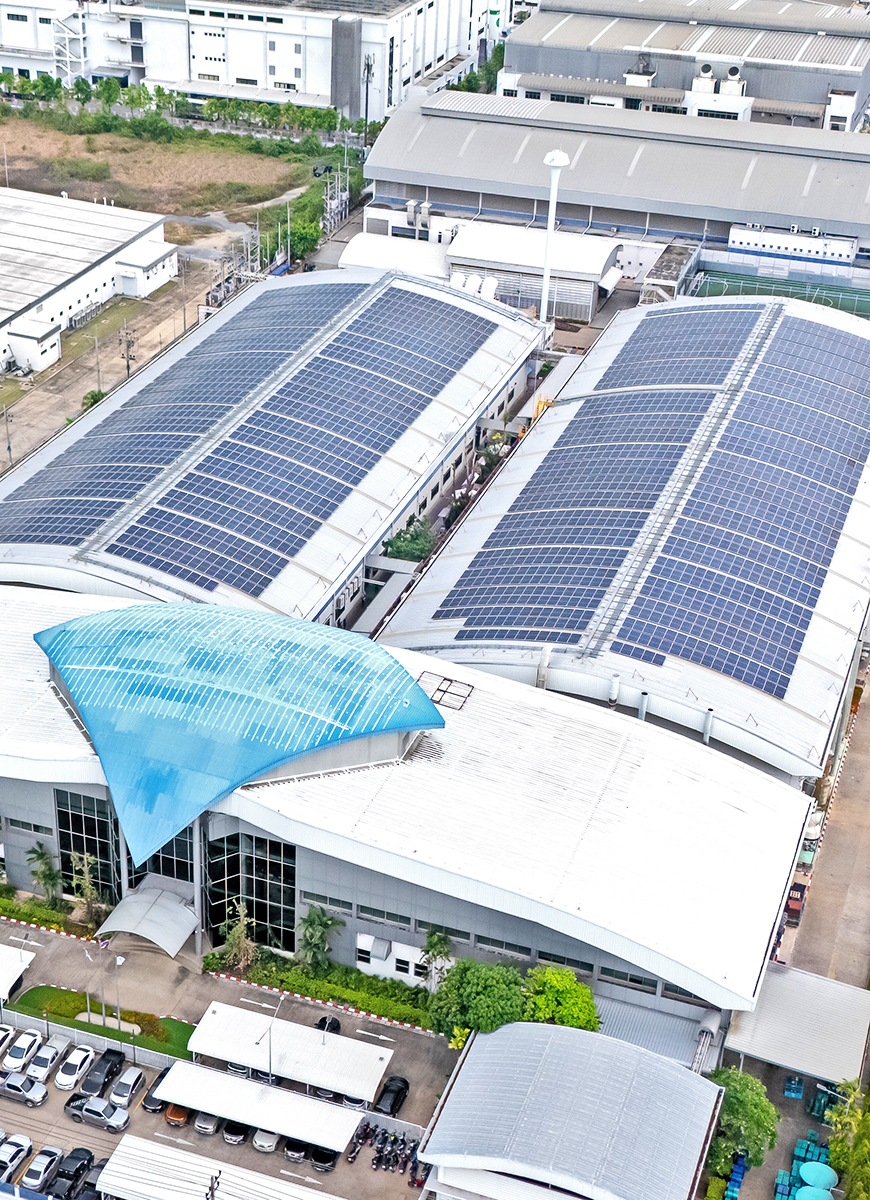

We place great importance on the sustainable use of natural resources and environmental stewardship. Our initiatives include reducing greenhouse gas emissions through the use of renewable energy, implementing sustainable waste management practices based on the 3Rs (Reduce, Reuse, Recycle) and organizing tree-planting activities to help absorb carbon dioxide.